Ultrasonic cleaning

Ultrasonic Cleaning

“Cleanliness is next to Godliness”

Vantopia are proud to announce that we are now ultrasonically cleaning the gearboxes we recondition. As far as we know of, we are the only company to be offering this service as part of our transaxle/gearbox rebuild service for VW Type 2 Bay gearboxes and VW T25/T3 air-cooled and water-cooled gearboxes including 4 speed, 5 speed and Syncro gearboxes or transaxles both Petrol and Diesel.

For more parts of the process please see here

What Ultrasonic cleaning is

Ultrasonic cleaning has been used industrially for decades, particularly to clean small intricate parts, and to accelerate surface treatment processes. Ultrasonic cleaning is used for a variety of applications from cleaning greasy engine components, window blinds, newly machined and fabricated components, aircraft components, medical and surgical instruments, precision optics and laboratory glassware, heat exchangers jewellery and even restoring old vinyl records.

Other manual or automated washing systems that utilise degreasers whether it be solvent or water-based detergents which work by agitation whether it be by brush or high-pressure jets. Ultrasonic cleaners on the other hand work by using the power of imploding (not exploding) microscopic bubbles in a process called cavitation, with the use of specially formulated cleaning fluids.

The ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency. This creates compression waves in the liquid of the tank which ‘tear’ the liquid apart, leaving behind many millions of microscopic ‘voids’/’partial vacuum bubbles’ (cavitation). These bubbles collapse with enormous energy; temperatures and pressures on the order of 5,000 K and 135 MPa are achieved; however, they are so small that they do no more than clean and remove surface dirt and contaminants. The higher the frequency, the smaller the nodes between the cavitation points, which allows for cleaning of more intricate detail. Our models sweep through a number of frequencies to allow for not only coarser but also fine cleaning.

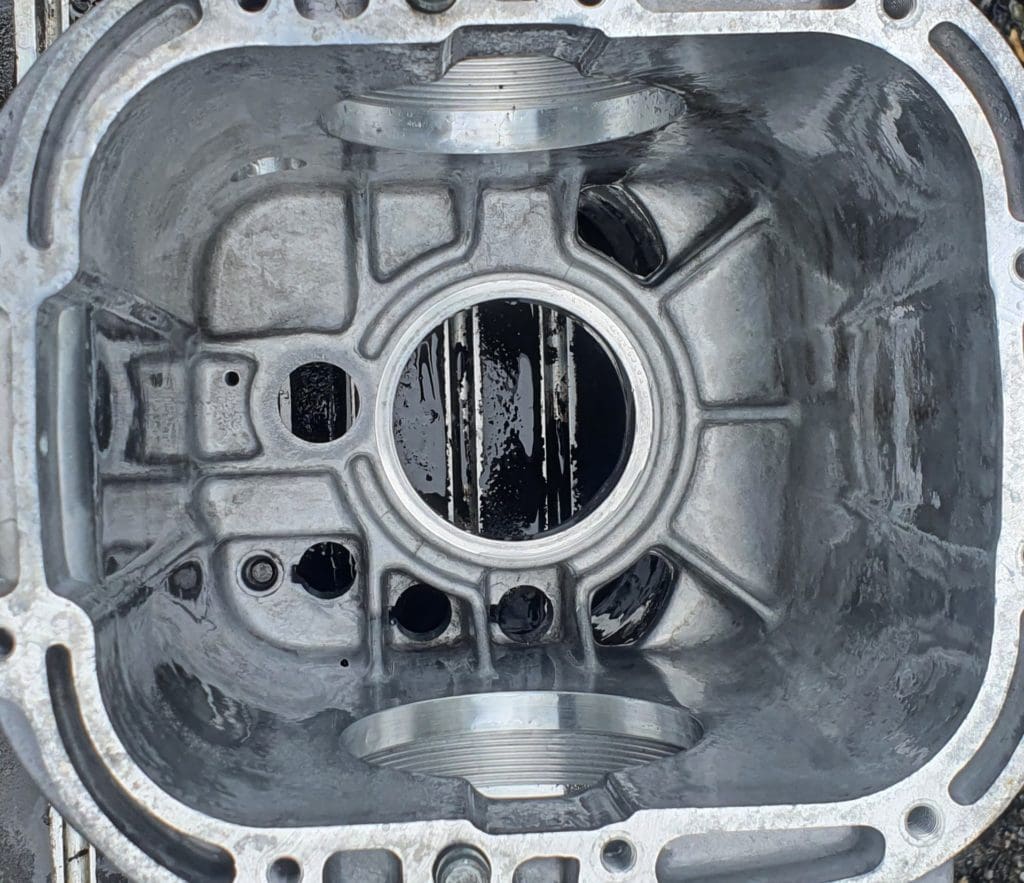

This process is a far superior, the microscopic bubbles reaching places where one cannot even see. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces.

Ultrasonic cleaning for the VW T3/T25 Gearbox

Ultrasonic cleaning for the VW T3/T25 gearbox. Thus, through the process of cavitation ultrasonic cleaners are able to clean various other metal and plastic products difficult or impossible to clean by other methods.

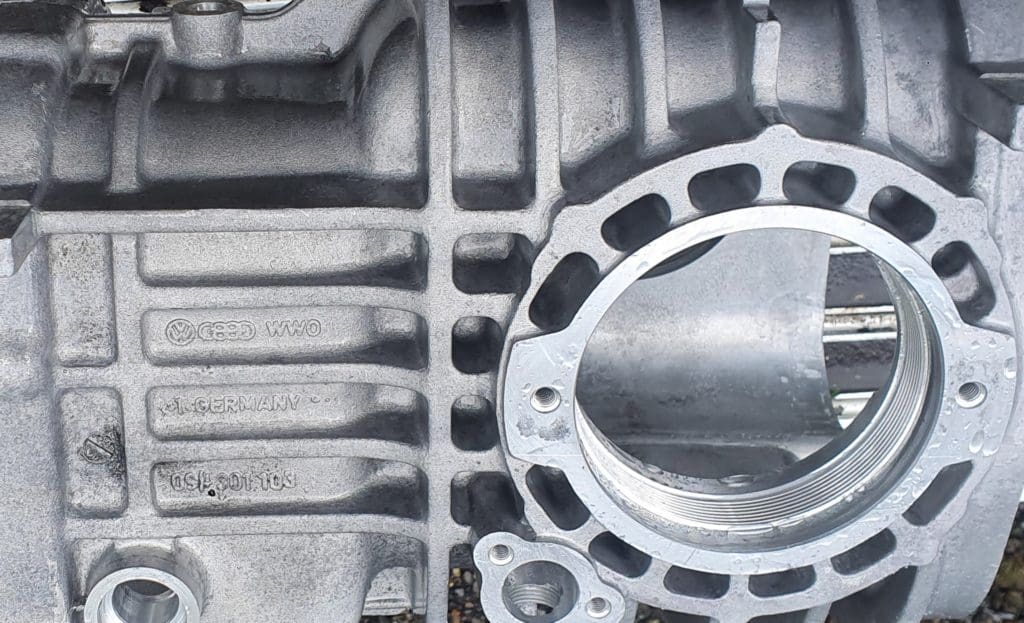

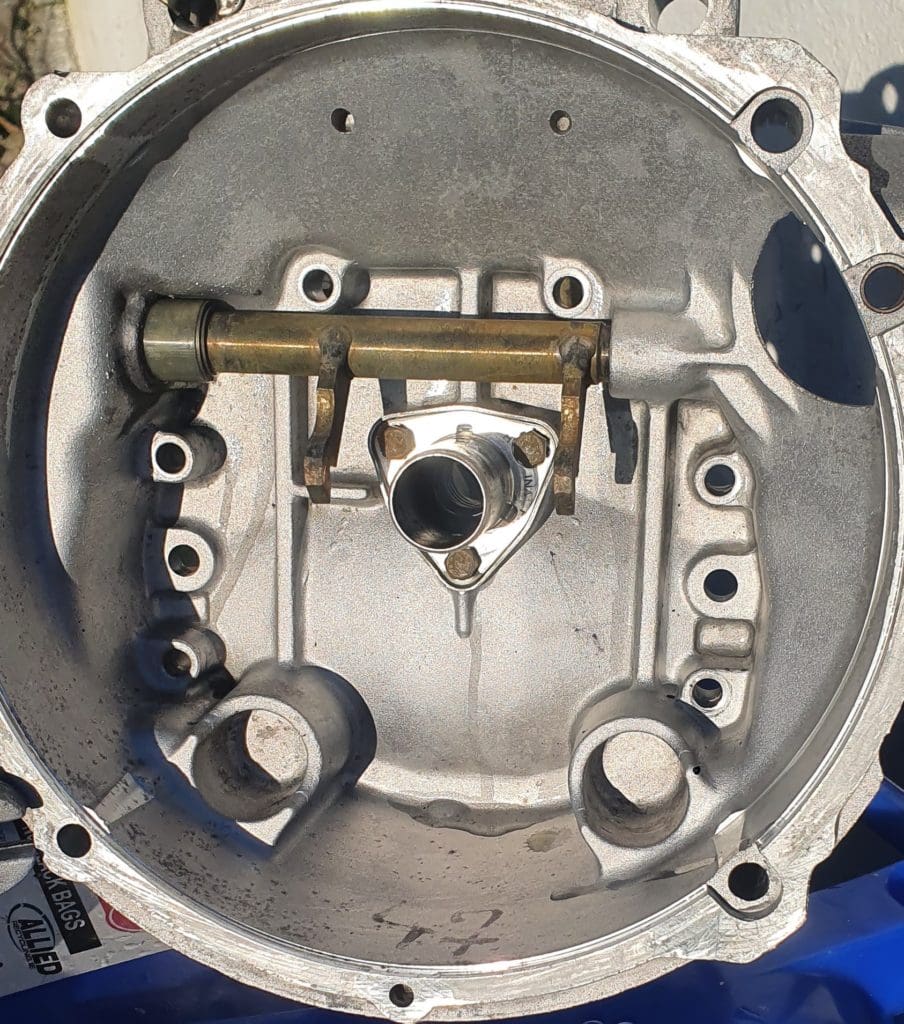

For gearbox rebuilding this is a game changer and allows for a superior build. Components and the cases themselves are restored back to the same level or even superior cleanliness when built by VW in the factory.

Ultrasonic cleaning allows for much better inspection of your parts. For the rebuild and reassembly of your VW T3/T25 gearboxes and components its is almost like rebuilding a new gearbox. Due to the lack of surface contaminants all the threads are clean, mating surfaces and machined faces are all spotlessly clean. This allows for much finer tolerances and will also will help to preserve your components for much longer due to lack of contaminants passed into the your new clean oil.